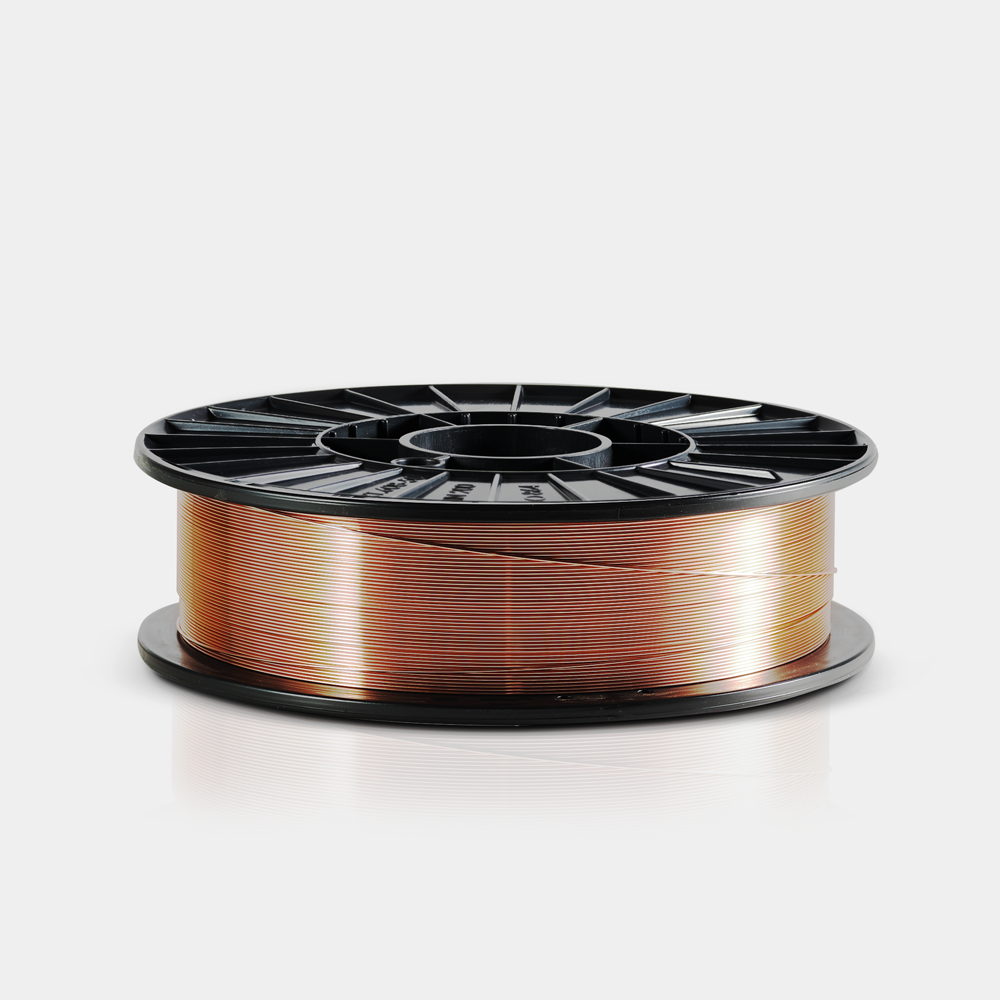

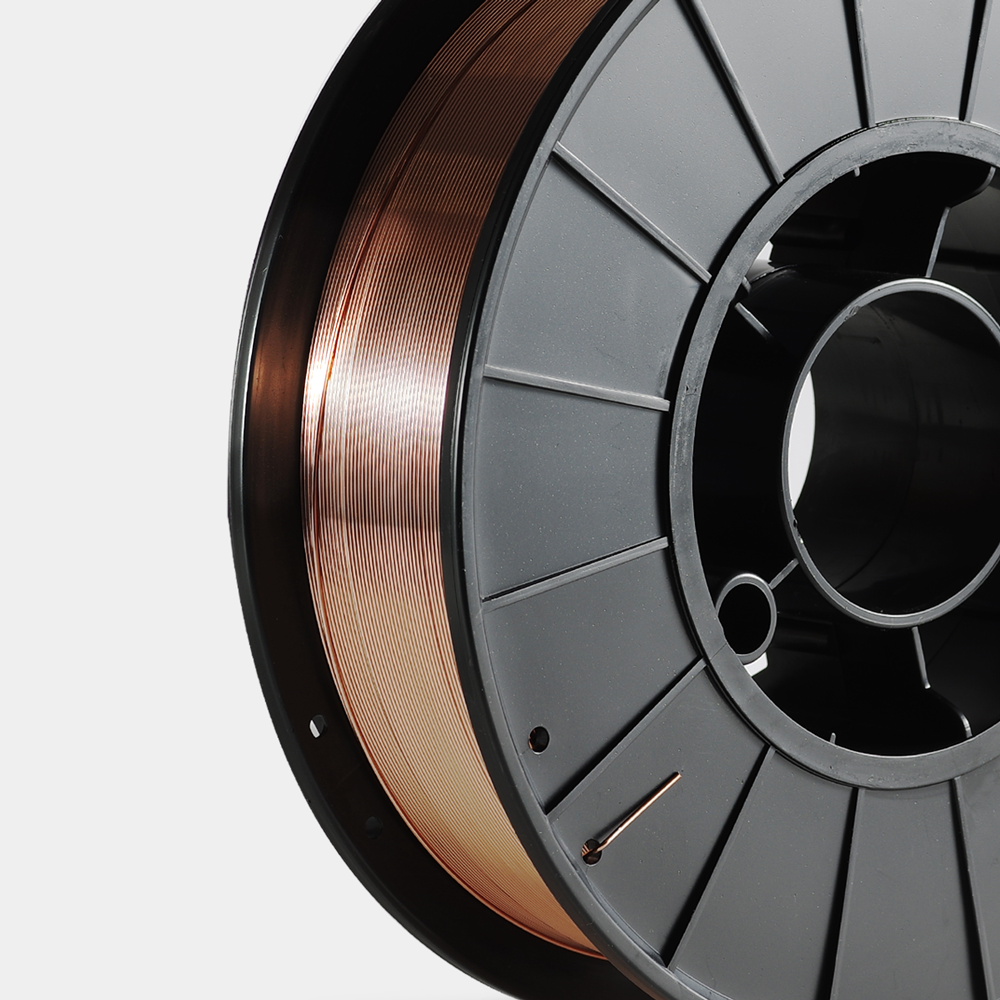

4130

AISI 4130

4130 is a low alloy, copper-coated steel wire designed for TIG, MIG and

submerged arc welding of heat-treatable, lowalloy steels such as the SAE 4100 series and 8630 as well as steel castings with similar hardening characteristics. A pre-heat temperature of 300°F-350°F is required for some of the higher carbon grades in order to prevent cracking. Many

other grades can be welded without a preheat.

TYPICAL WIRE CHEMISTRY (%)

- | ER80S-B2 |

|---|---|

C | 0.310 |

Mn | 0.520 |

P | 0.012 |

S | 0.023 |

Si | 0.280 |

Cr | 0.930 |

Mo | 0.200 |

TYPICAL MECHANICAL PROPERTIES OF WELD METAL

Proper heal treatment will produce a tensile strength of 150,000 to 160,000 psi.

RECOMMENDED SHIELDING GAS

98% Argon (Ar) and 2% Oxygen (O2) or pure Argon (Ar)

download Technical datasheets

download Certification