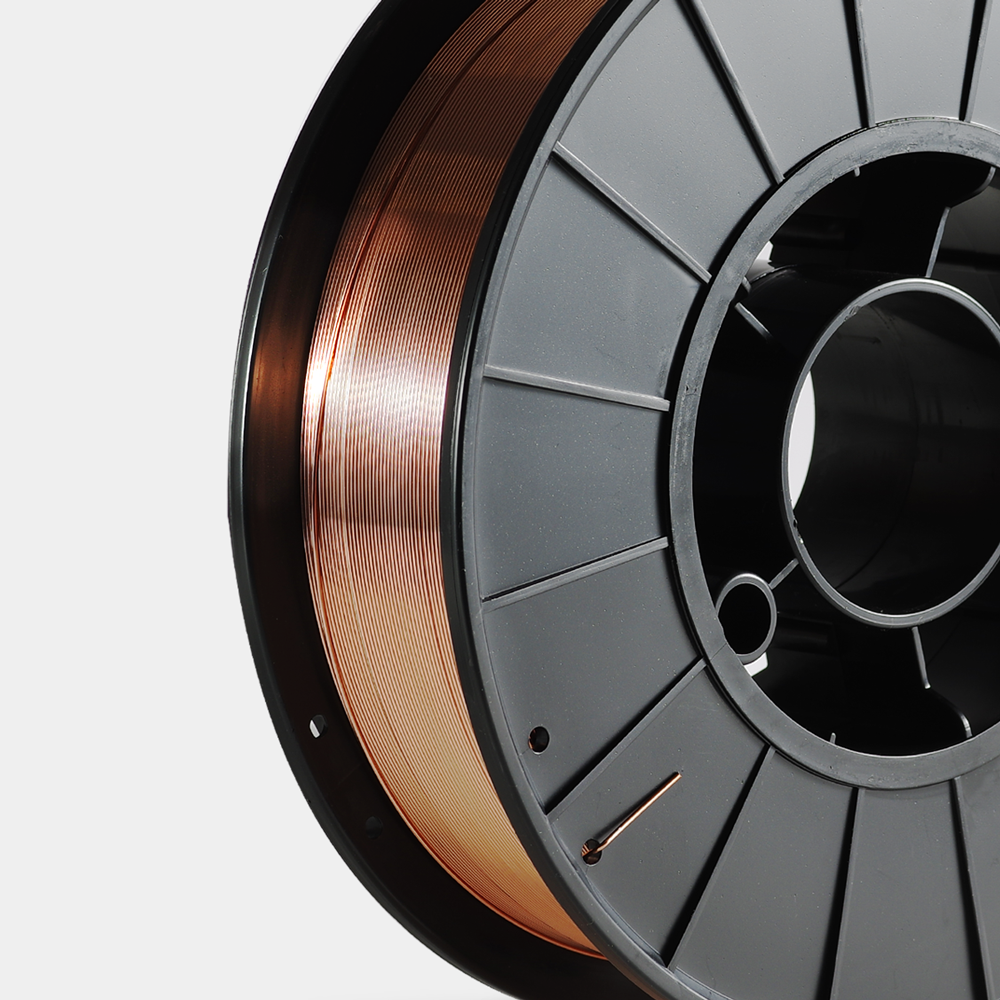

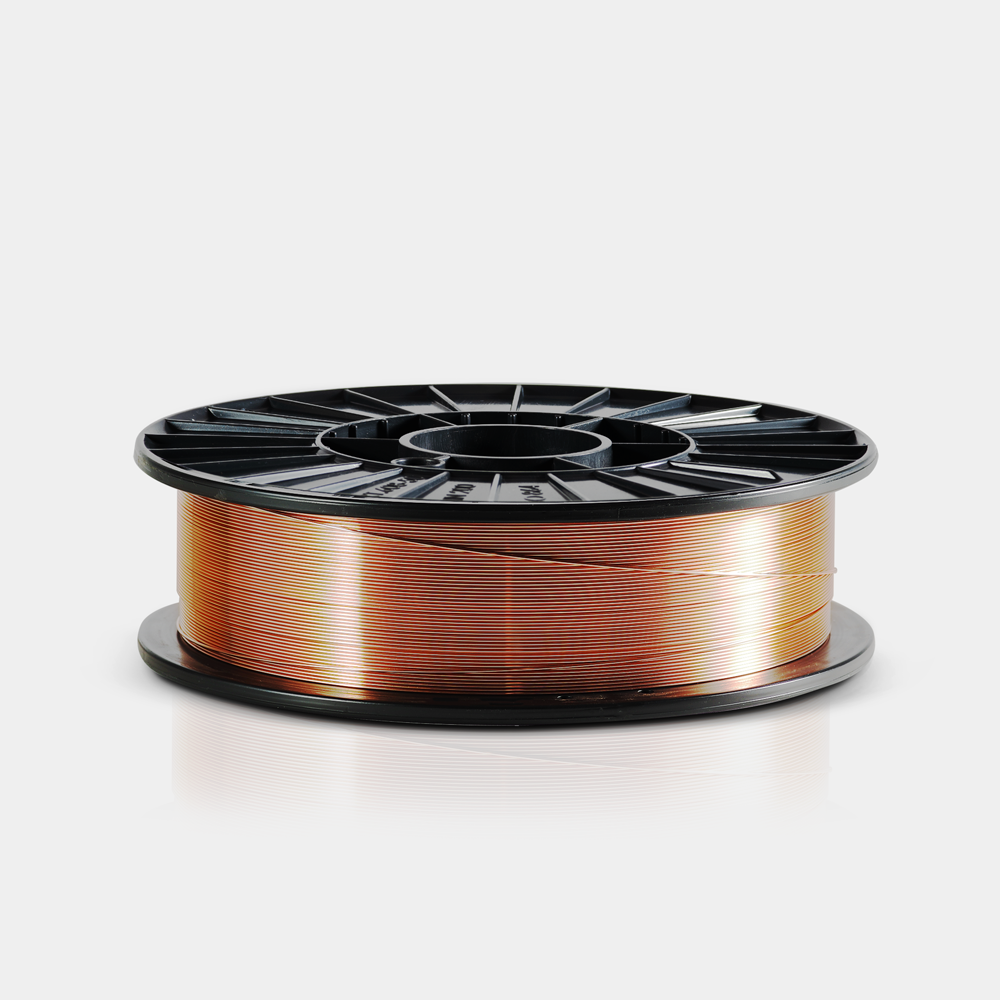

Er100s-1

AWS A5.28 Class ER100S-1

ER100S-1 was developed for welding high strength low alloy steel plates such as HY80, HY100 and other similar steels. This wire produces high tensile strength, high impact resistant weld deposits that retain their toughness to –70°F making it suitable for low temperature and critical applications. ER100S-1 can be welded at an interpass temperature as low as 300°F.

USA 100S–1 was developed for welding high strength low alloy steel plates such as HY80, HY100 and other similar steels. This wire produces high tensile strength, high impactresistant weld deposits that retain their toughness to –70F making it suitable for low temperature and critical applications. USA 100S–1 can be welded at an interpass temperature as low as 300F.HY80 and HY100 steels, military vessels, all–position weldingPreheat and interpass of 300°F may be required.

100SUSA 100S–1 was developed for welding high strength low alloy steel plates such as HY80, HY100 and other similar steels. This wire produces high tensile strength, high impactresistant weld deposits that retain their toughness to –70F making it suitable for low temperature and critical applications. USA 100S–1 can be welded at an interpass temperature as low as 300F.HY80 and HY100 steels, military vessels, all–position weldingPreheat and interpass of 300°F may be required.–1 was developed for welding high strength low alloy steel plates such as HY80, HY100 and other similar steels. This wire produces high tensile strength, high impactresistant weld deposits that retain their toughness to –70F making it suitable for low temperature and critical applications. USA 100S–1 can be welded at an interpass temperature as low as 300F.HY80 and HY100 steels, military vessels, all–position weldingPreheat and interpass of 300°F may be required.

TYPICAL WIRE CHEMISTRY (%)

- | ER100S-1 | AWS Spec |

|---|---|---|

C | 0.10 | 0.07-0.12 |

Mn | 0.63 | 0.40-0.70 |

Si | 0.46 | 0.40-0.70 |

P | 0.012 | 0.025 max. |

S | 0.012 | 0.025 max. |

Mo | 1.06 | 0.90-1.20 |

Cr | 2.55 | 2.30-2.70 |

Ni | 0.10 | 0.20 max. |

Cu | 0.11 | 0.35 max. |

Typical mechanical properties of weld metal (C02 shielding gas)

- | ER100S-1 | AWS Spec |

|---|---|---|

Yield strength (psi) | 92,000 | 88,000 min |

Ultimate tensile strength (psi) | 105,000 | 100,000 min |

Elongation in 2" (%) | 17 | 15 min |

Charpy V-notch at -60 F (ft. lbs) | 60 | 50 min |