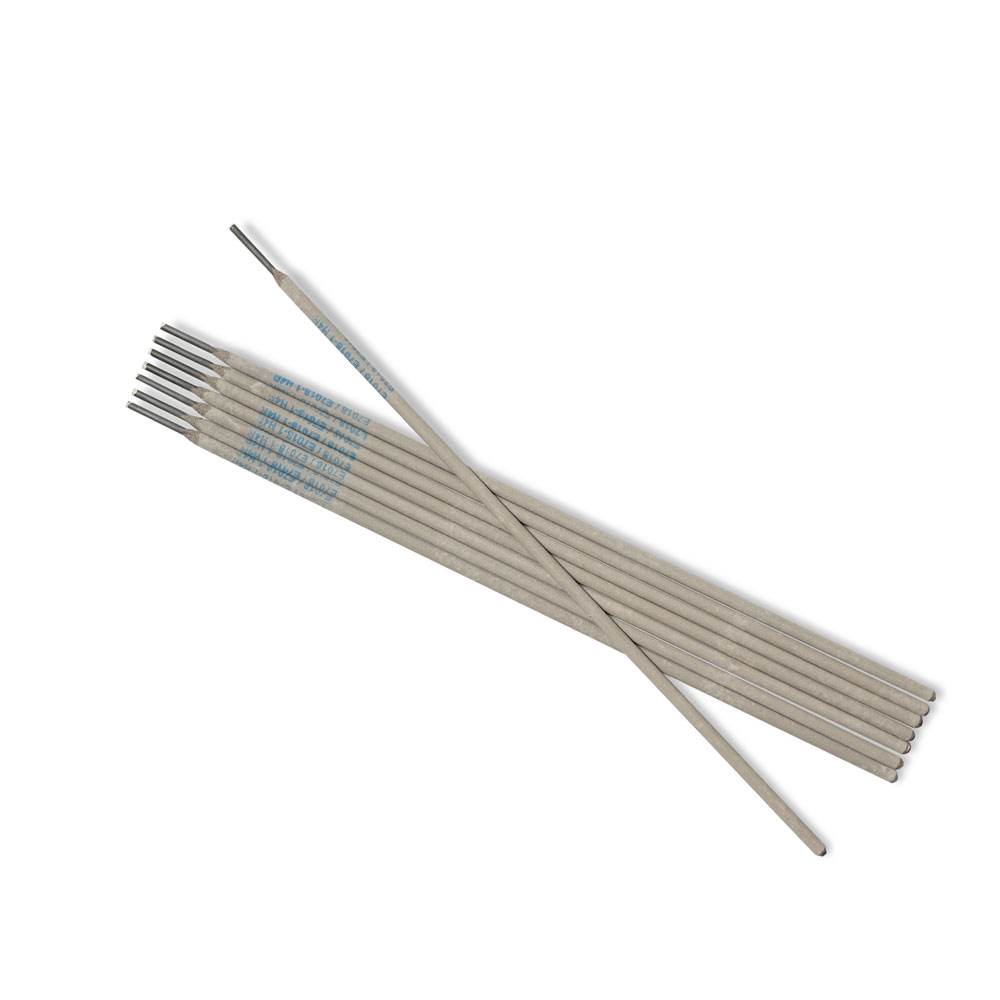

EAGLE STRIKE 7018+ (E7018-1)

AWS A5.1 E7018-1 H4R, E7018 H4R

ASME SFA 5.1 E7018-1 H4R, E7018 H4R

QUICK STRIKE TIP eliminates arc freeze. Easy re-strike for efficient welding.

GENERAL PURPOSE LOW HYDROGEN mild steel electrode recommended for all-position welding of low to high carbon steels typically used in barge/ship building, offshore drilling rigs, power, petrochemical and boiler plants, etc.

SPECIALLY FORMULATED to yield high quality welds with excellent operator appeal and very easy, self-peeling slag removal and is easy to control with a smooth, stable arc, flat or slightly convex, finely rippled bead appearance and superb wetting in. Good for poor to tight fit-ups on new or fatigued steel, skip or tack welding in flat, horizontal, vertical or overhead positions.

UNIQUE COATING FORMULATION resists moisture pickup that helps ensure cracking or porosity issues commonly found with excess moisture and allows up to 9 hours of exposure listed in AWS D1.1

EAGLE-STRIKE 7018+ carries the AWS E7018-1 H4R designation and shows high impact values up to -50°F.

Applications:

barge/ship building, offshore drilling rigs, power, petrochemical and boiler plants, etc.

TYPICAL WIRE CHEMISTRY (%)

- | AWS SPEC | TYPICAL WELD METAL |

|---|---|---|

C | 0.15 | 0.07 |

Mn | 1.60 | 1.42 |

Si | 0.75 | 0.28 |

P | 0.035 | 0.015 |

S | 0.035 | 0.009 |

Ni | 0.30 | 0.04 |

Cr | 0.20 | 0.06 |

Mo | 0.30 | 0.008 |

Va | 0.08 | 0.007 |

Typical weld metal properties

- | AWS Spec | Weld Metal |

|---|---|---|

Ultimate tensile strength (psi) | 70,000 min | 85-100,000 |

Yield Strength (psi) | 58,000 min | 65-73,000 |

Elongation in 2" (%) | 22% min | 23.9-27% |

Charpy V-notch at -50°F (ft. lbs) | 20 ft lb min | 103 |

-20°F | - | 59 |

Diffusible Hydrogen | <4.0 | 2.76 |