Er90s-B3

AWS A5.28 Class ER90S-B3

90S-B3 is a low alloy fillerdesigned to produce high strengths on2 1/4 & Cr-1 Mo steels found in high temperature/high pressure piping and vessels. It may also be used on carbon steels to Cr-Mo base metals. Controlled preheat, interpass and postheat treatment may be needed to avoid cracking.

TYPICAL WIRE CHEMISTRY (%)

- | ER90S-B3 | AWS Spec |

|---|---|---|

C | 0.10 | 0.07-0.12 |

Mn | 0.63 | 0.40-0.70 |

Si | 0.46 | 0.40-0.70 |

P | 0.012 | 0.025 max. |

S | 0.012 | 0.025 max. |

Mo | 1.06 | 0.90-1.20 |

Cr | 2.55 | 2.30-2.70 |

Ni | 0.10 | 0.20 max. |

Cu | 0.11 | 0.35 max. |

Typical mechanical properties of weld metal (C02 shielding gas)

- | ER90S-B3 | AWS Spec |

|---|---|---|

Yield strength (psi) | 80,500 | 78,000 min |

Ultimate tensile strength (psi) | 94,500 | 90,000 min |

Elongation in 2" (%) | 19 | 17 min |

Charpy V-notch at 0 F (ft. lbs) | N/A |

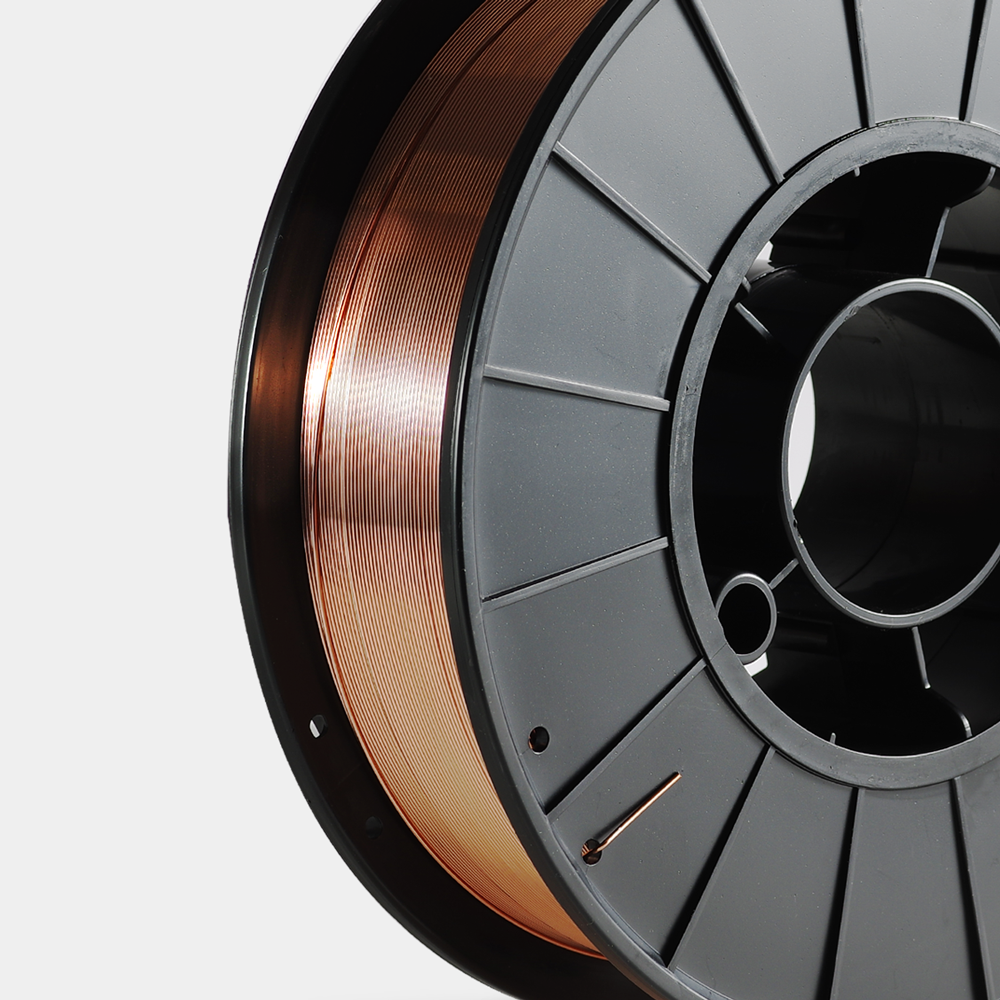

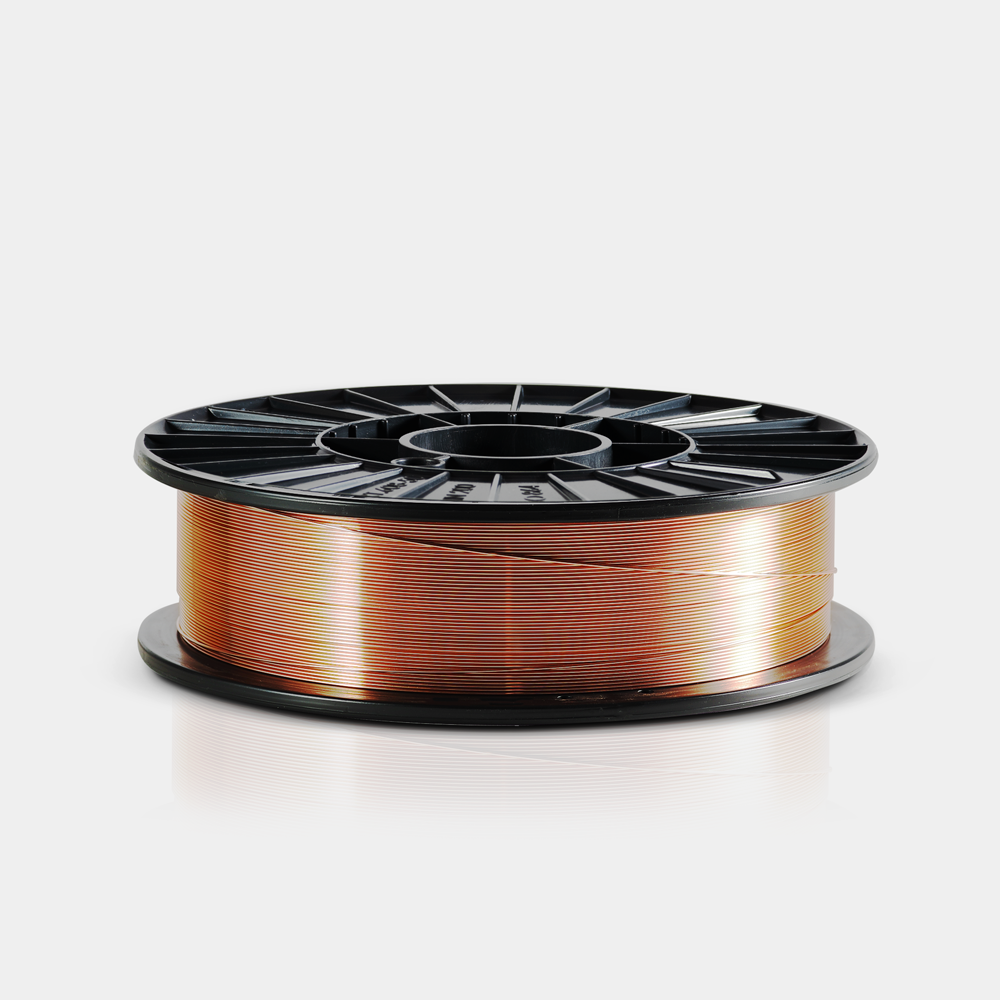

| WA Part No. | Description | UPC Code |

| TC 90S-B3 04 | ER90S-B3 .030 X 2 LB SPOOL | 034496964171 |

| TC 90S-B3 05 | ER90S-B3 .030 X 11 LB SPOOL | 034496964188 |

| TC 90S-B3 06 | ER90S-B3 .030 X 33 LB SPOOL | 034496905822 |

| TC 90S-B3 07 | ER90S-B3 .035 X 2 LB SPOOL | 034496905839 |

| TC 90S-B3 08 | ER90S-B3 .035 X 11 LB SPOOL | 034496905846 |

| TC 90S-B3 09 | ER90S-B3 .035 X 33 LB SPOOL | 034496950204 |

| TC 90S-B3 15 | ER90S-B3 .045 X 2 LB SPOOL | 034496905860 |

| TC 90S-B3 16 | ER90S-B3 .045 X 11 LB SPOOL | 034496905877 |

| TC 90S-B3 17 | ER90S-B3 .045 X 33 LB SPOOL | 034496905884 |

| TC 90S-B3 24 | ER90S-B3 1/16 X 33 LB SPOOL | 034496905891 |